The importance of Wear Rings in a hydraulic cylinder

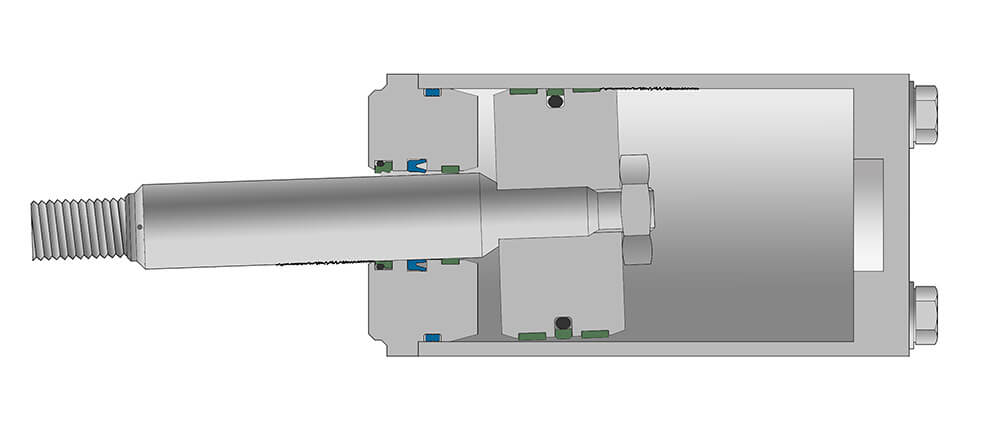

Hydraulic cylinders are designed to generate thrust or traction force longitudinally.

All cylinders are subject to withstand radial or longitudinal loads: whether they are due to the weight of the metal parts, to the radial clearances or to not perfect alignments, even in the best design situation, around 10-15% of the hydraulic force applied to the cylinder turns into a radial load.

In many applications, where for example the hydraulic cylinders work horizontally, or mechanically in simultaneous pairs (see eg sheet metal bending machines), or undergo efforts perpendicular to their axis, the radial loads not foreseen in the design phase can reach very high values.

The mechanical impact of this load causes excessive wear of the guide components present in the stem bushings and on the cylinder piston heads, the deterioration of the sealing elements, and, finally, the cylinder seizure.

The use of specific Wear Rings in plastic or composite material, especially in applications with horizontal and long travel, greatly increases the reliability of the hydraulic cylinder extending the life of the gaskets and guaranteeing the absence of unwanted "leaks" for the entire duration of the their functional life.

These rings can ensure that the sliding components of the cylinders are adequately supported against radial loads, and move correctly in the longitudinal direction.

Guide ring functions in hydraulic cylinders:

- They act as a linear guide, providing radial support for the moving metal components of the cylinders.

- They preserve the Sealing System from excessive loads and radial mechanical forces and deformations.

- They protect the seals from uneven wear.

- They prevent the seals extrusion caused by non-uniform radial clearances, keeping the metal components moving in a concentric position and guaranteeing the tolerance values and the radial design gaps.

- They prevent metal / metal contact and consequent seizing.

How to choose the correct Wear Rings for each application:

Traditionally, rod and piston bushings made of ferrous and non-ferrous metal were used as driving components in the cylinders. The typical ferrous material was gray cast iron, while the non-ferrous material was bronze.

The production of bushings or inserts of this type for piston or rod support has proved to be problematic and costly over time, both for the cost of the material and for the complexity of machining the metal parts, which had to be made with extreme precision and very small clearances.

A valid solution to contain costs, which makes it possible to design simpler metal parts while at the same time guaranteeing their perfect functioning, is the use of plastic or composite wear rings, housed in special seats, which allow the realization of metal parts with wider coupling games while ensuring perfect axiality.

It is very important to pay particular attention to the choice of the most suitable material and to the correct dimensioning of the Wear Rings, considering the typical application data such as:

- Type of application

- Forces in play in the cylinder (Linear thrust force, Offset thrust force, Safety coefficient)

- Contact materials

- Speed

- Temperature

- Type of Fluid

The different materials of which guide rings can be made have specific characteristics that make them suitable for different types of application (low friction, heavy application, etc.).

Each material has specific characteristics and a different tolerance of the radial load, so it is important to choose the most suitable material so that the total guide surface is adequate to withstand the total radial load of the cylinder considering a design safety coefficient.

ATS has a complete range of Wear Rings, of different materials, low friction self-lubricating or suitable for heavy-duty applications, made from spools (tapes) or preformed and ready to be inserted in their seats.

The Wear Rings series ATS-N, ATS-K ed ATS-F are the best choice to protect the components of the Sealing System from excessive radial force, as well as to protect the cylinders from possible mechanical damage due to the transverse load.

For more information on Guide Rings, see the Products page.

Italiano

Italiano